PEM Electrolyser Cell

- Home

- PEM Electrolyser Cell

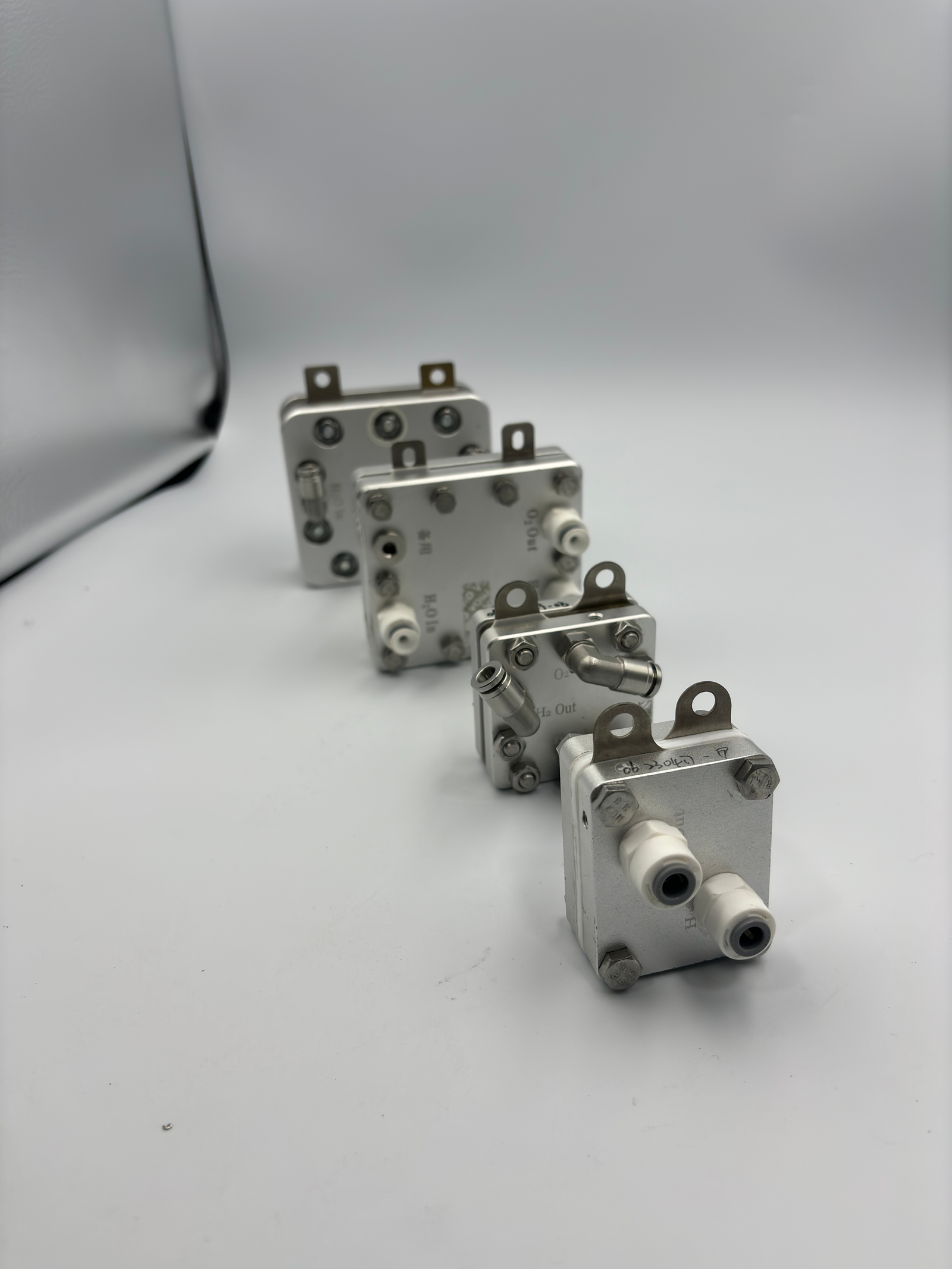

PEM Electrolyser Cell

- Material: High-quality stainless steel, titanium, or other corrosion-resistant materials

- Packaging: Customizable quantities available upon request

- Working Area Options: 3 cm x 3 cm,5 cm x 5 cm , 3.5 cm X3.5 cm ,5.5 cm x 6.5 cm

- Components: Cell body, electrodes, membrane, gasket, flow field plates, end plates, current collectors, gas diffusion layers

Introduction

The PEM (Proton Exchange Membrane) Electrolyser Cell is designed for efficient water electrolysis to produce high-purity hydrogen and oxygen. These cells are engineered with precision to ensure optimal performance, durability, and reliability. Available in various working areas, the PEM Electrolyser Cell is ideal for research and development, pilot projects, and small-scale hydrogen production systems.

Specification

Material :

- Cell Body: High-quality stainless steel or titanium for corrosion resistance

- Electrodes: Platinum or iridium-coated titanium for high efficiency and durability

- Membrane: Perfluorosulfonic acid (PFSA) polymer

- Gasket: EPDM or Viton for sealing and chemical resistance

- Flow Field Plates: Graphite or titanium with appropriate flow channel design

- End Plates: Stainless steel or titanium for structural stability

- Current Collectors: Gold-plated or nickel-plated copper

- Gas Diffusion Layers: Carbon cloth or carbon paper

Operating Conditions :

- Temperature Range: 20°C to 80°C

- Pressure Range: Up to 2 bar

- Current Density: Up to 1 A/cm²

Performance Charateristics :

- Hydrogen Production Rate: Varies with working area and operating conditions

- Efficiency: >80% under optimal conditions

Applications

- Research and Development: Ideal for studying the performance of new catalyst materials, membranes, and electrolyser designs.

- Pilot Projects: Suitable for small-scale hydrogen production and demonstration projects.

- Renewable Energy Integration: Used in systems integrating renewable energy sources for green hydrogen production.

- Industrial Processes: Applied in industries requiring high-purity hydrogen, such as electronics manufacturing, chemical processing, and metal refining.

- Educational Use: Utilized in academic settings for teaching and demonstrating principles of water electrolysis and hydrogen production.

Order Information

| S.No | Product Name | Dimension(L XW) | Port Type | Surface Area | Part No |

|---|---|---|---|---|---|

| 1 | PEM Electrolyser Fixture | 3 cm X 3 cm | Parallel | 9cm² | TES-CF-PEM-9 |

| 2 | PEM Electrolyser Fixture | 3.5 cm X 3.5 cm | Parallel | 12.25 cm² | TES-CF-PEM-12 |

| 3 | PEM Electrolyser Fixture | 5 cm x 5 cm | Parallel | 25 cm² | TES-CF-PEM-25 |

| 4 | PEM Electrolyser Fixture | 5.5 cm X 6.5 cm | Parallel | 35.75 cm² | TES-CF-PEM-35 |

Customization

Custom size and specifications are available upon request. Please contact our sales team for more information.